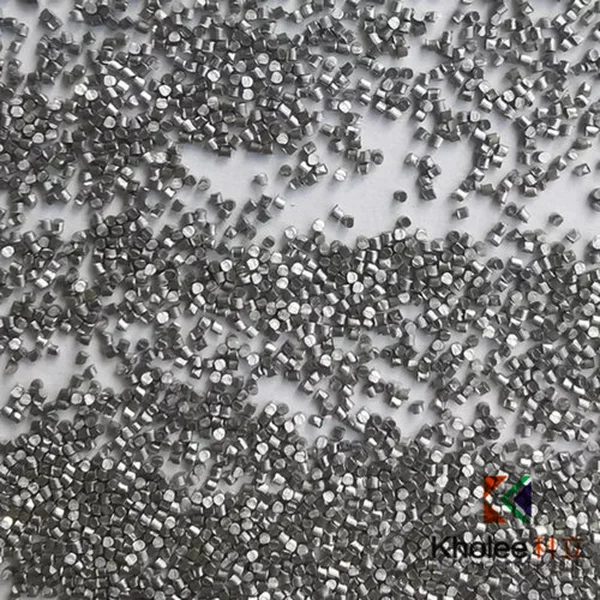

Stainless steel cut wire shot, is made by cutting stainless steel wires. The stainless steel cut wire shots are available as cut or conditioned.

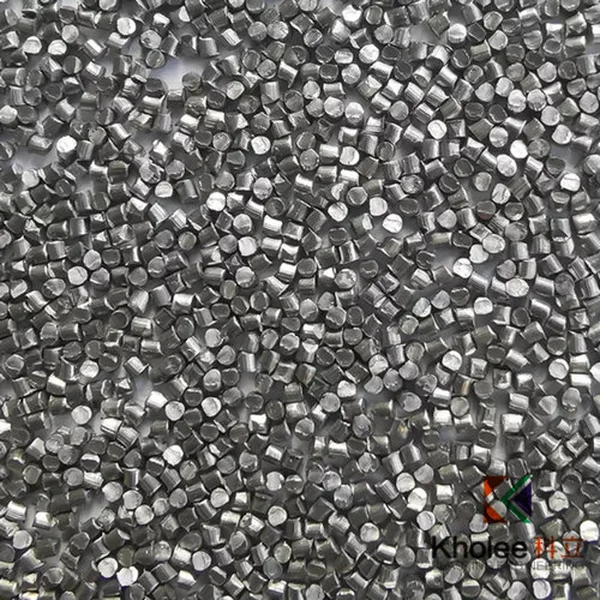

The stainless steel shots as cut, which is also called for cylindrical cut wire shots, has the shape edges during the cutting process.

The cylindrical stainless steel cut wire shots is used as blasting material in various industries such as castings, aluminium die castings, brass components and other metals on which ferrous contamination is harmful.

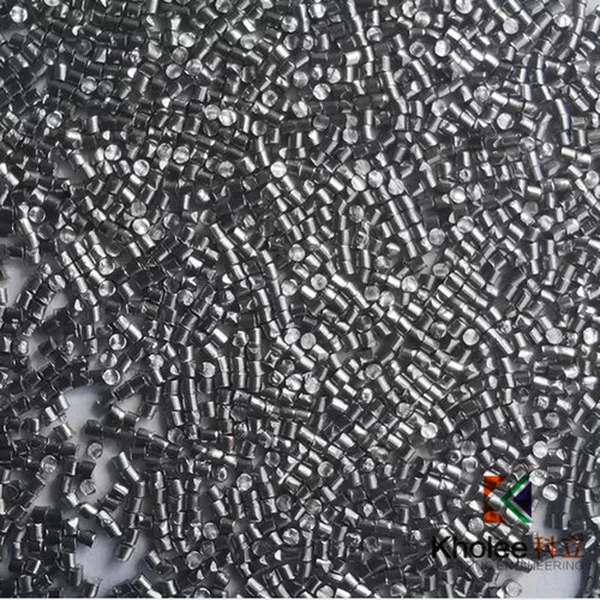

Stainless steel shots conditioned, which is also called for Spherical conditioned stainless steel cut wire shots, is made by stainless steel wire after cutting and conditioning process. During the process, we can obtained several conditioned forms G1 (normal conditioned), G2 (double conditioned) and G3 (special conditioned), where G3 is the perfect rounded particle.

Spherical conditioned stainless cut wire shots are used more in the shot peening process in different industries such as automotive industries, aerospace industry, medical industry, shipping industry etc.

Application |

■ Blast cleaning, deburring ■ Surface finishing ■ Surface-improvement ■ That all types of aluminum castings ■ Die castings ■ Non-ferrous metals and special alloys ■ Concrete and natural stones |

Advantages: |

■ Great durability ■ Has small blasting times ■ Gives bright appearance ■ Results in rust-free surfaces ■ Reduced wear of blast cleaning equipment ■ Has low waste disposal costs ■ Is a dust-free blasting process |

Physical Properties |

■ Cylinder shape edges / semi round / prefect round shape ■ Hardness (new grain) approx.: 308 ~509 HV ■ Specific gravity approx. 7.46~7.93 g/cm3 ■ Bulk density 4.20 – 4.50 kg/dm3 |

Blasting System |

■ Air Blasting System ■ Wheel Blasting |

Chemical Composition |

● Stainless Steel SUS410 /SS410 C≤0.15, Cr11.5~13.5, Ni 0.6 , Mn≤1.0, P≤0.04, S≤0.03, Si≤1.0 ● Stainless Steel SUS430 /SS430 C≤0.12, Cr16.0~18.0, Ni 0, Mn≤1.25, P≤0.04, S≤0.030, Si≤0.75 |

Available Sizes | Average Hardness |

Grain number — Size in mm 0.2mm/ 0.3mm / 0.4mm / 0.5mm / 0.6mm / 0.8mm / 1.0mm / 1.2mm / 1.5mm / 2.0mm / 2.5mm Other grades are available on request | 308 ~509 HV 32 ~50 HRC, Max Deviation ± 3.0HRC |

Tensile Strength | Ervin Recycle |

1300~2200 Mpa | 7000 times |

Shape | Metallurgical Microstructure |

● As Cut: cylindrical ● CCW / G1 Conditioned: corners pre-rounded ● DCCW / G2 Conditioned: semi-rounded ● SCCW / G3 Conditioned: perfect rounded | ● SS201 / SS202 / SS301/ SS304: Austenite ● SS410: Martensite ● SS430: Ferrite |

Density | Package |

● Specific gravity approx. 7.46~7.93 g/cm3 ● Bulk density 4.20 – 4.50 kg/dm3 | ● 25 kg bags on pallet up to 1 ton ● 1 ton loose in big bag |