- Home

- About Us

- Products

- Shot Blasting Machines

- Steel Plate Blasting Painting Line

- Steel Plate Shot Blasting Machine

- Roller Conveyor Shot Blasting Machine

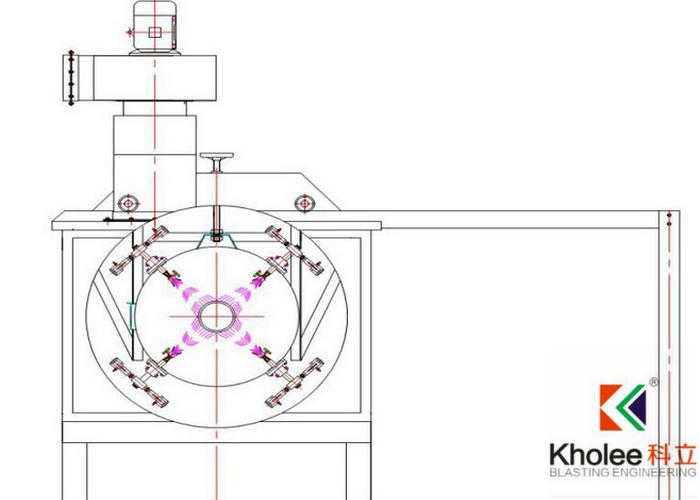

- Steel Pipe Shot Blasting Machine

- Spinner Hanger Shot Blasting Machine

- Pass Through Monorail Shot Blasting Machine

- Portable Shot Blaster

- Tumble Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Shot Blasting Machine for Casting Shell Removal

- Shot Blasting Machine for Casting

- Blast Wheel Replacement Parts

- Dehumidifiers

- Vacuum Recovery

- Blast Rooms

- Paint Spray Rooms

- Airless Paint Sprayers

- Blasting Painting Lines

- Portable Blast Machine & Accessories

- Dustless Vacuum Blaster

- Metal Blasting Abrasive

- Dust Collector

- Shot Blasting Machines

- Industries

- News

- Download

- Feedback

- Contact Us

- Blog

- Home

- About Us

- Products

- Shot Blasting Machines

- Steel Plate Blasting Painting Line

- Steel Plate Shot Blasting Machine

- Roller Conveyor Shot Blasting Machine

- Steel Pipe Shot Blasting Machine

- Spinner Hanger Shot Blasting Machine

- Pass Through Monorail Shot Blasting Machine

- Portable Shot Blaster

- Tumble Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Shot Blasting Machine for Casting Shell Removal

- Shot Blasting Machine for Casting

- Blast Wheel Replacement Parts

- Dehumidifiers

- Vacuum Recovery

- Blast Rooms

- Paint Spray Rooms

- Airless Paint Sprayers

- Blasting Painting Lines

- Portable Blast Machine & Accessories

- Dustless Vacuum Blaster

- Metal Blasting Abrasive

- Dust Collector

- Shot Blasting Machines

- Industries

- News

- Download

- Feedback

- Contact Us

- Blog